Our Work With Supply Chains

As a Rockay customer, we always want you to be able to make an informed decision about the products you choose to invest in, and as such we have laid out the pathway from fabric to finish, so that you have the complete picture.

Way before our first sock was sewn, sourcing and selecting the right supply chains for Rockay has and remains today, a top priority. Our top non-negotiable is that we only ever work with factories that have already been audited, with all the relevant certifications in-place.

The industry is evolving and adapting at such a rapid pace that it’s a luxury for us to have partners that are built so in-line with our own core values and principles.

Working hand-in-hand, together we have elevated Rockay to new heights, adhering to our sustainable performance message, while ensuring wellbeing and fair and proper conditions of all our workforce, in-house and on the factory floors.

Get To Know Our Suppliers

Our supply chain partners are very much a part of Team Rockay, equals, and that we are all in this together – so naturally, wellbeing and human rights is of the utmost importance.

Rockay scours the globe for suppliers that can bring to life our sustainable performance message. We look to align with those that share our goals – to reduce carbon footprint and make meaningful impacts socially. Only then do they make the grade.

Rockay partners with like-minded finished-goods factories, and as such we are proud to be able to deliver quality products with a social and environmental conscience. No matter how much development and evolution goes on, now and in the future, the one constant is that sustainability will remain a business imperative for us and our working supply chains.

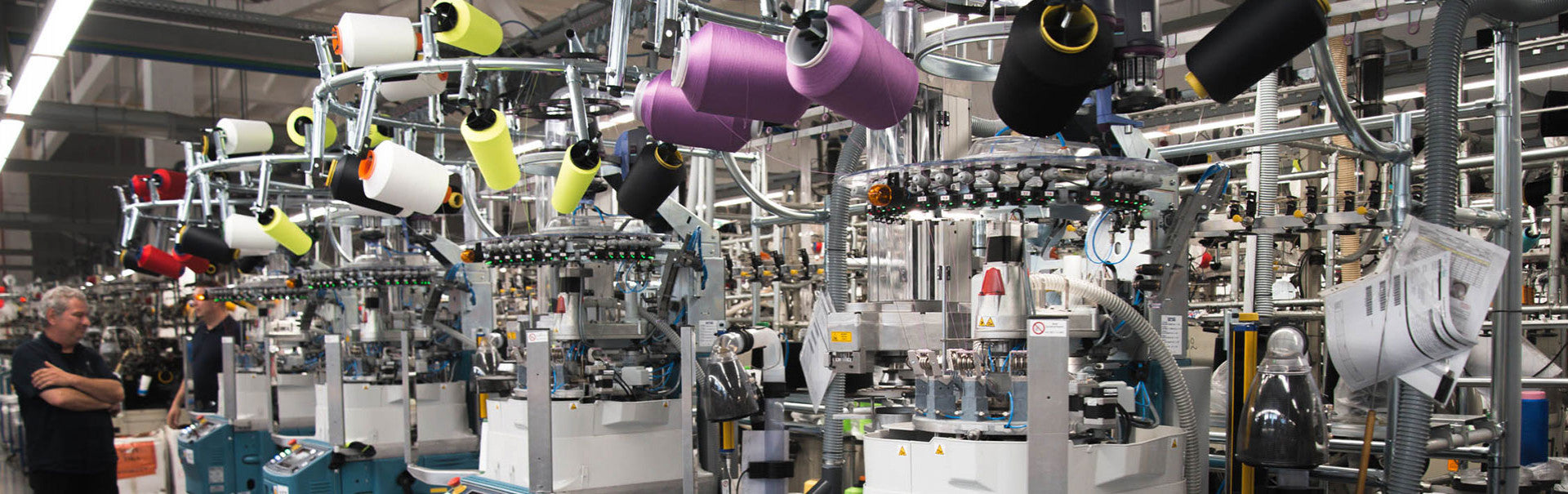

Our apparel is made in Europe by tried and trusted suppliers who are innovating and leading the way forward in all forms of quality, wellbeing and sustainability. Our socks too, are made in Europe, and we have an active partnership with the supplier that continues to encourage and utilize yarns that are reducing harmful environmental impacts.

Our Factories

Our management team, as well as only the most trusted third-party audits, travel on-site to factories to do the absolute most in regards to due diligence, leaving no stone unturned, to ensure that everything is being done to deliver our customers the most high-end quality product.

We look at everything, from environmental practices and policies, wages and benefits, health and safety, working hours, harassment and discrimination, as well as any kind of forced labor. Any ‘red flags’ will not be taken lightly, and we aspire to do good and support local communities through job opportunities.

The following steps are taken to ensure proper practice at the source:

Verification Process

Risk assessment and social practices are fulfilled by our finished-goods factories.

Auditing

Engage a complete audit of the facilities and working conditions to ensure all criteria are met.

Certification

We require complete commitment and compliance with our factory suppliers on employee safety, human rights and the relevant environmental certificates. All of our factories are certified in accordance with ISO 9001:2015, a global standard that defines requirements for a quality management system (QMS).

Our Environmental Regulations

Environmental regulations, along with record keeping, are outlined by the Global Recycled Standard (GRS), and our partners obtain regular certification. We monitor all relevant legal requirements related to energy use, wastewater, emissions and waste management.

Additionally, our chemical regulations exclude inherently problematic substances that are classified as dangerous to human health and/or to the environment by REACH. The exclusion of substances and mixtures classified with particular hazard codes or risk phrases, as well as the exclusion of substances that do not comply with ZDHC’s Manufacturer’s Restricted Substance List.